Blog

At SWA, we’ve worked on over 2.2 million square feet of multifamily and dormitory buildings that used CAR dampers to balance large-scale ventilation systems. Here’s what we’ve learned about constant airflow regulators (CARs) and measuring air flow.

Many multifamily buildings we work on at SWA use large, central energy recovery ventilation (ERV) systems to provide balanced ventilation. These big systems serve dozens, sometimes hundreds of apartments. Balancing these systems—making sure the right amount of air flows to and from each apartment—can be a challenge.

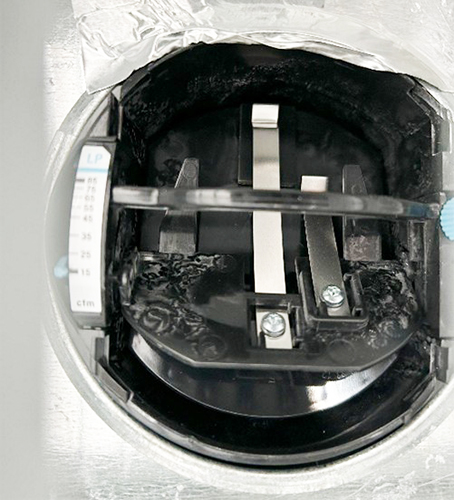

One strategy we’ve found to be very effective for balancing ERV systems is using constant airflow regulators (CARs).1 CARs contain variable dampers, and the damper position varies with air velocity. As velocity increases, the damper closes; when velocity is lower, the damper opens. The result is a fairly constant volume of air flow over a defined pressure range.

We’ve found that CARs in every supply branch and exhaust branch help balance the system to deliver design flow rates. While this can be challenging, there are several reasons why it’s important to deliver design flow rates: thermal comfort, humidity control, energy efficiency, and program/code compliance.

These devices aren’t foolproof; they need to be selected and installed properly. Of the 3.5 million square feet of certified Passive House projects in our books, over 2.2 million square feet of multifamily and dormitory buildings included CAR dampers and were successfully balanced.2 But there have been some instances where the devices were not properly installed.

We’ve seen the following can go wrong during installation:

For good performance, installers need to be trained and knowledgeable about proper installation. And CARs are only one piece of a good system. Proper system design is also critical.

If there’s not sufficient static pressure at a branch duct, there’s nothing a CAR can do to increase air flow. Eliminating duct leakage can help with this in many systems, and we highly recommend a product like Aeroseal to make ducts airtight.

Some building certification programs (e.g. Phius) require verification that target ventilation rates are delivered when the building is complete. Pitot or anemometer traverse measurements in ducts may be the best ways to measure air flow, but branch ventilation ducts are usually inaccessible when buildings are complete and ready for final testing.

When testing at registers—which are usually the only accessible option—SWA has had the most success using a fan-assisted flow hood, specifically the Acin FlowFinder.

The principle behind fan-assisted flow hoods is that they don’t add resistance to the air stream. Hoods without fans can work, but these add some resistance to air flow—if only just a little bit.

A hood that’s not fan assisted can lead to flow measurements that are different than flow during normal operation. The fan in the FlowFinder is controlled to keep the pressure within the hood equal to pressure in the room, so in effect, the register “sees” normal room pressure.

Since the FlowFinder and CARs both compensate for air velocity or pressure, we’ve heard concerns that there could be a feedback loop that yields unstable or inaccurate results. We’ve yet to encounter this issue while testing ventilation in thousands of apartments. After powering the hood and reaching a steady state (~30 seconds), we see consistent, repeatable readings.

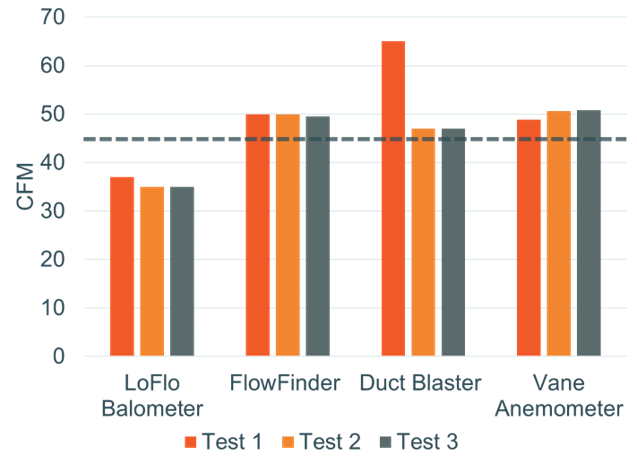

In a recent Phius project in Connecticut, SWA raters measured ventilation flow rates with four different instruments in a sample of apartments. The four-story building has three ERVs on the roof serving 86 apartments, an amenity space, and common areas. Each supply and exhaust branch has an Aldes CAR3 installed.

This is not a fan-assisted device. The “LoFlo” device has a listed flow range of 10-500 cfm. Many larger hoods don’t accurately measure the lower ventilation rates in some apartments.

A fan-assisted capture hood.

In these tests, the duct blaster was configured as a fan-assisted capture hood by controlling the fan to keep the pressure at the register equal to room pressure.

This vane anemometer comes with small capture hoods. The hoods didn’t entirely cover the registers in this building, so the edges were taped in these tests. This could introduce some error.

Where possible, static pressure in each branch was measured by snaking a probe through the register and past the CAR. See below.

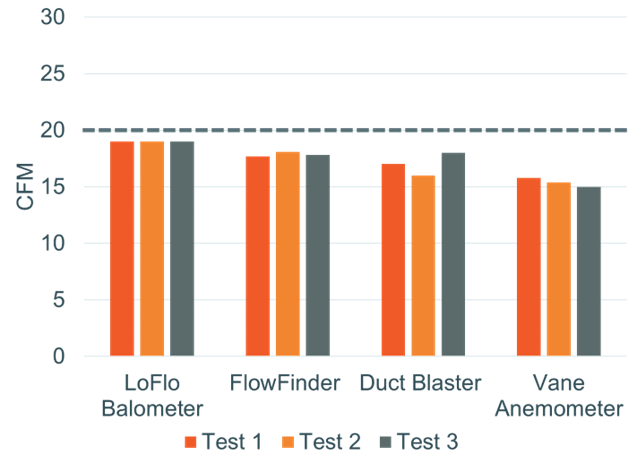

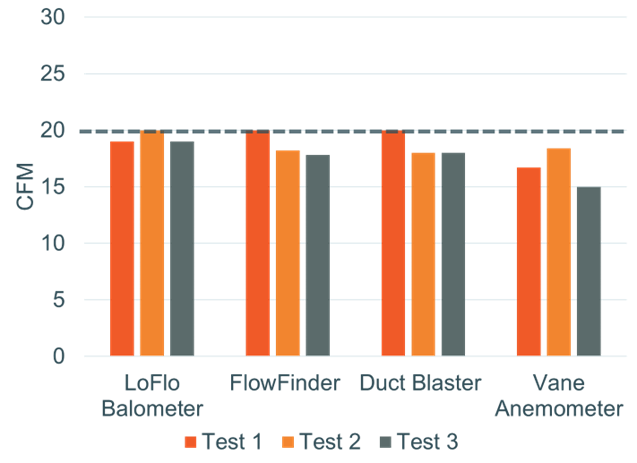

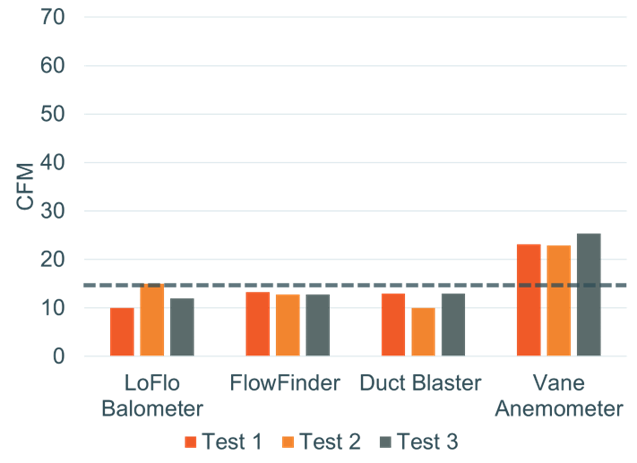

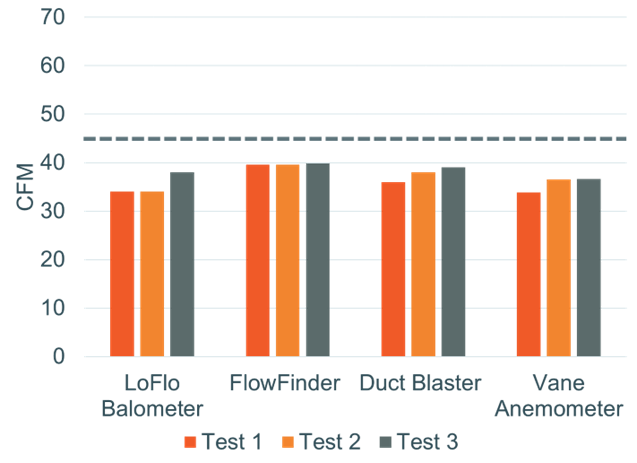

To check the repeatability of each flow measurement device, all six registers were tested three times with each instrument. The results were as follows:

Exhaust #1

Exhaust #2

Exhaust #3

Supply #4

Supply #5

Supply #6

Overall, most instruments provided readings near the design flow rates. There were a few trends, such as:

It’s worth noting that the static pressure in many branches was near (or below) the low end of the pressure range listed for the CAR. This isn’t surprising, as CARs are installed where system pressure is very low—right behind the registers. In some cases, it appears that balancers adjusted the CAR setting higher than the design value to allow more flow. SWA has observed balancers using CARs like a manual balancing damper to get more flow when pressures are low.

We tested one other supply register (#7 below) where measured flow rates were lower than the 45 cfm design. When checking the CAR settings, we found there was no CAR present; balancers may have removed it entirely to try to increase flow.

CARs can’t help if there’s not enough static pressure to work with. In register #7, the measured air flows from the different devices were slightly closer to each other than measurements from supplies that did have CARs, but this was only one register. It’s not enough data for us to draw any conclusion.

Supply #7

In addition to being close to design flow rates, the FlowFinder provided the most repeatable readings. The average range (max-min) of the three readings was:

This is a small sample, but it matches our experience that the FlowFinder provides consistent, repeatable readings.

Based on our experience testing hundreds of multifamily buildings with central ventilation systems, we recommend the following.

Have questions? Looking for a rater for your next project? Contact us to talk to an expert!

Contributors: Lois Arena, Director, High Performance Building Solutions; Robb Aldrich, Principal Mechanical Engineer; Karla Butterfield, Sustainability Director; Shari Rauls, Sustainability Consultant

Footnotes

Steven Winter Associates